Why should I use concrete?

Concrete provides a number of benefits, for both interior and exterior applications.

- It’s durable – it lasts for years with very little maintenance.

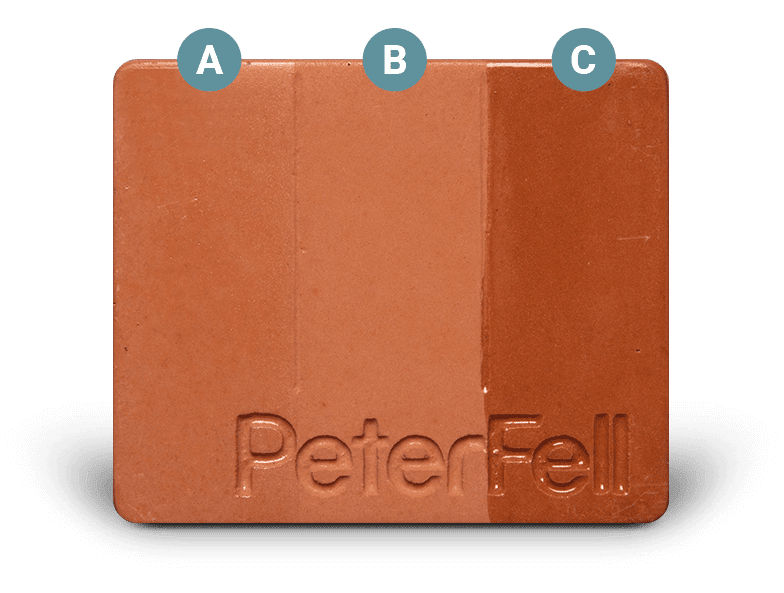

- It’s versatile. You can use it for driveways, patios, pathways, benchtops and floors. And with over 80 colours to choose from and a range of sealers, you can create a look that’s uniquely yours.

- It creates a more comfortable environment. Concrete absorbs heat during the day to help cool your space and then releases that heat when the temperature drops at night. That means you’ll save on your energy costs too.

- It’s easy to keep clean so you can maintain a healthier living space.

- It’s good for the environment because maintaining buildings with concrete flooring requires less energy and resources to maintain. In fact, concrete is now being viewed as a key material component of New Zealand’s commitment to more sustainable development.

- Concrete has the best fire resistance of any building material.

- It has good acoustic qualities, so you can create a quieter environment.

Where can I buy PeterFell coloured concrete from?

You can buy the PeterFell coloured concrete of your choice from any ready mix concrete supplier in New Zealand (contact us for details of your local supplier).

Please note that we don’t sell coloured concrete direct to the public.

Who lays coloured concrete?

PeterFell coloured concrete can be laid by any concrete contractor. That’s because PeterFell colour is added to the concrete at the ready mix concrete plant and the concrete is then laid exactly the same way as standard concrete. Your contractor will determine the texture and finish of the concrete based on the look you want to achieve. Please contact us for contractors in your area.

How should my concrete be laid?

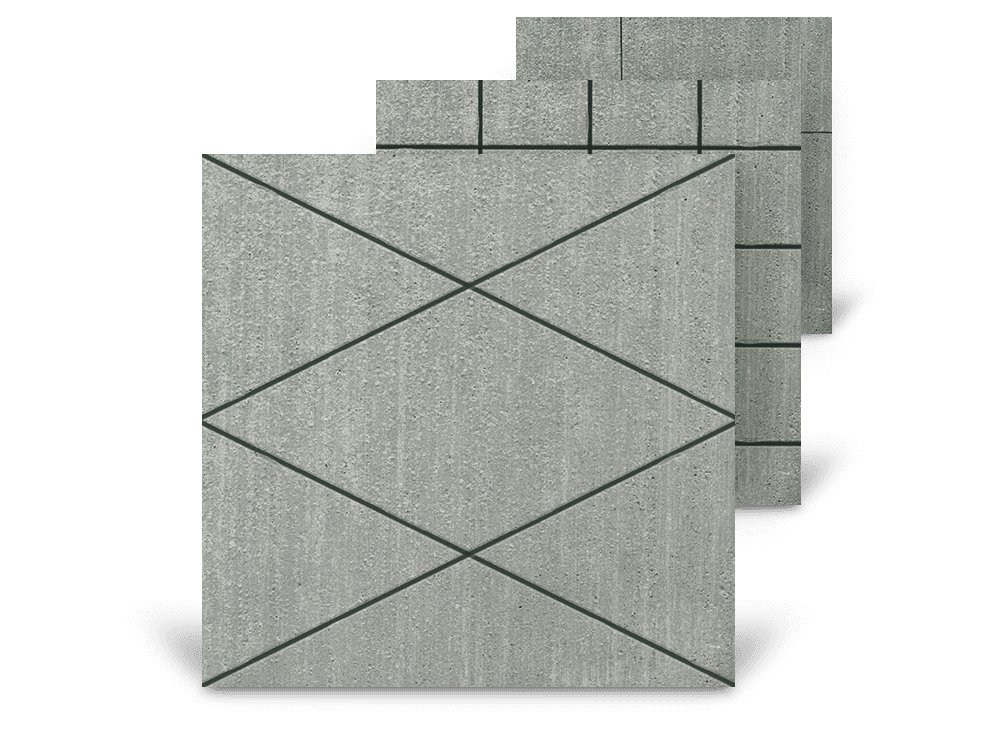

Your concrete should be laid in accordance with Standards New Zealand NZS3109 and textured in accordance with Standards New Zealand NZS3114. In addition to these guidelines, further detail on the required texture must be specified. The texturing of the coloured concrete surface at time of placement is what determines the slip resistance. The texture also influences the final concrete colour, and therefore the overall appearance of your finished surface so you need to ensure your contractor knows exactly what look you want to achieve.

View technical documents

Will concrete crack?

Cracking can happen. As concrete hardens, excess water evaporates which causes the concrete to shrink, and this is what can cause cracking. The proper use of Construction Cuts, proper site preparation, and good concrete placing will significantly reduce the risk of any cracking. Even then, cracks can occur. Contact us to find out more or view information on cracking by the Cement and Concrete Association of New Zealand.

Do I have to colour all of my concrete floor?

You can use PeterFell coloured concrete on as much of the concrete flooring surface as you want. When doing this, the coloured concrete should be placed first and taken to at least one metre past where other flooring (such as timber and carpet) is to be used.

If the flooring is a combination of coloured concrete and plain concrete, care must be taken in placing, especially in regard to cross contamination of grey concrete into the coloured area. Contractors need to be vigilant when finishing to avoid contaminating the coloured concrete with plain concrete from work boots and equipment. All tools should be thoroughly cleaned when moving from plain to coloured concrete.

Can I use underfloor heating?

Yes, concrete can used with all types of underfloor heating. The main thing you need to consider when using any heating system is the placement of Construction (expansion) Cuts. These cuts are required in all concrete, coloured or plain.

Care should be taken in the preparation and placement of piping, wiring, or heating coils. The placement of all sub-floor components should be clearly defined prior to the placing and cutting of the concrete to ensure successful integration of the heating system into the concrete floor. Heating components are usually placed 500mm from any Construction Cut. All components should be secured in place at regular intervals to prevent movement during concrete placement.

Which flooring systems can use coloured concrete?

Colour can be added to virtually all concrete flooring system – slab on grade, pod system or suspended slabs. Contact us and we can discuss how the PeterFell System can be used in your project.

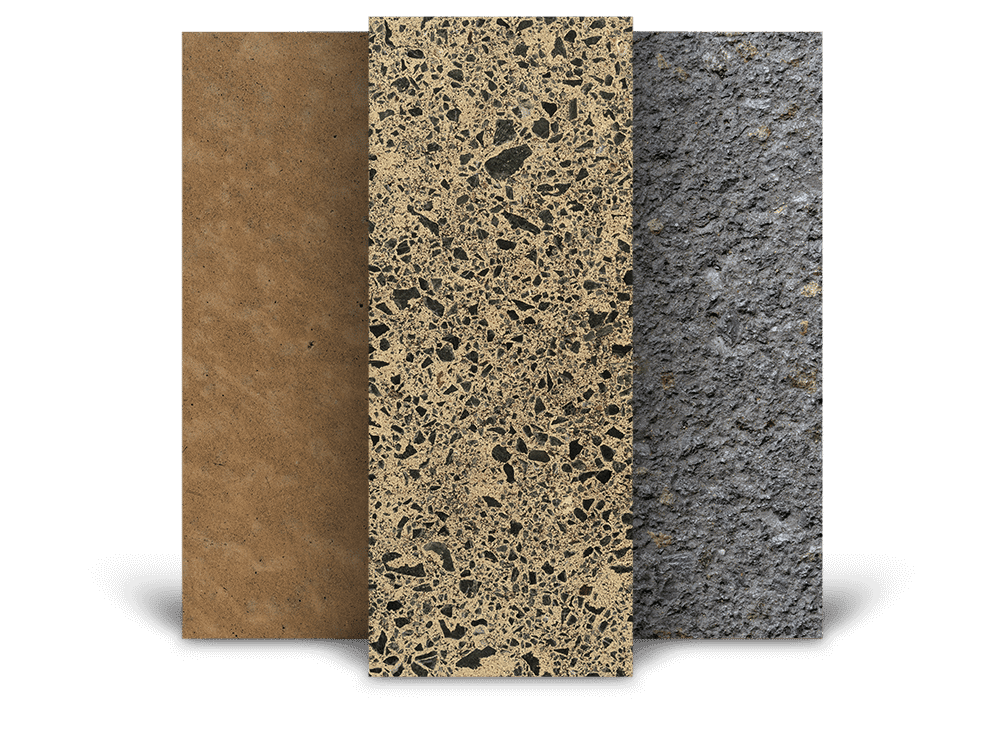

Can I use PeterFell coloured concrete in exposed aggregate concrete?

Yes, PeterFell coloured concrete can be integrated into projects that use exposed aggregate (or stoney) concrete.

The main thing you need to consider when choosing exposed aggregate concrete is the look of the aggregate itself. In New Zealand there are wide range of natural aggregates offering a range of different sizes, colours, and combinations of stones. We recommend that you contact your local concrete supplier to find out what’s available in your area.

You can then use the PeterFell System to provide a complimentary (or contrasting) background colour to the aggregate selected. The PeterFell Finishing Process is also recommended, even in situations where no colour is added to your concrete. Sealing exposed aggregate concrete not only protects the surface from staining and marking, but also enhances the natural colour of the aggregate.

Can I use PeterFell coloured concrete in a concrete overlay?

Yes, you can use the PeterFell System to colour concrete overlays exactly as for standard concrete flooring. All concrete overlays should be undertaken with due diligence to ensure optimal structural integrity. We recommend that all overlays are bound to the existing substrate using an epoxy bonding agent.

The overlay should be approximately four times the average aggregate size with a minimum depth of 50 mm. For any overlay under 80 mm, cuts in the existing slab should be transferred to the overlay, and all cracks should be ‘bandaged’. We strongly recommend that you talk to an engineer or concrete professional.

Can I use PeterFell coloured concrete in concrete stairs?

Yes. Stairs can be generated in situ, or precast off site and installed later. All in situ poured stairs should be placed by an experienced tradesperson. The boxing should be constructed so it can easily be dismantled and the face of the rise trowelled. Alternatively, the rise can be plaster rendered following placement and curing of the concrete. PeterFell oxides can be used in the plaster to approximate the concrete colour.

Can I use admixtures in my coloured concrete?

Standard admixtures including air entrainer, set accelerators, set retarders, water reducing agents and superplastericisers will have very little effect on the PeterFell System.

However, calcium chloride based admixtures, or admixtures which alter the matrix of the cement, can affect the colour distribution and create colour ‘mottleyness’. We recommend that you use water retarders in hot weather to delay and control concrete set time. In cold weather, non-chlorine accelerators and/or superplastercises should be used to improve handling and performance of the concrete.

How do I cure my PeterFell coloured concrete?

“Curing” is where you maintain a satisfactory level of moisture content in the concrete following placement to allow proper hydration of the cement. All concrete should be cured in accordance with Standards New Zealand NZS3109.

This hydration gives the concrete its strength and durability. So as a first step in hot or exposed sites (i.e. areas that are prone to wind and extreme weather) we recommend that you use anti-evaporation compounds to stop rapid loss of moisture.

The length of the curing period depends on the properties required of the concrete, but usually last for several days through to several weeks. However, it is the first 24 hours which are the most critical, so curing should be closely monitored during this time.

Should I use a curing compound on PeterFell coloured concrete?

No curing compounds are to be used in the PeterFell System

Curing compounds form a film on the concrete surfaces that reduces water loss to aid concrete curing. However, this film prevents the sealer applied later from penetrating and binding to the concrete surface, which leads to delamination.

We recommend therefore that water is the only curing agent used on PeterFell coloured concrete floors. This should be applied to the surface in a mist or fine spray. Care should be taken when wetting the surface to ensure the concrete isn’t marked. Materials that retain water (such as sand or hessian cloth) can be used to aid curing, but again, you need to be careful that you don’t damage the concrete surface. Polythene sheets can also be used to stop water loss, and help protect the concrete during the curing process.

Contact us to find out more

How do I protect my concrete during construction / landscaping?

It’s important that you protect your concrete with polythene while any landscaping or construction is going on. We recommend you use black 250 micron sheets.

Concrete is porous, meaning it is easily stained and marked (which is also why you need to seal it). The coloured concrete will be the final surface applied, so it must be properly protected from staining and marking during construction and landscaping.

Given the durability of concrete it is not so much the physical damage to the slab that’s the problem, but more a case of liquid contaminants leaving stains and marks.

The polythene stops these contaminants penetrating into your concrete. Polythene also helps the concrete cure, maximising its durability.

Also, as the floor needs to be properly cured before sealing (at least 28 days after laying) it is recommended that it is protecting during curing.

To ensure even curing, wet the slab lightly prior to overlaying the polythene and make sure the polythene has no folds as this may lead to line mark staining. In exterior situations, hold the polythene in place with strong adhesive building or agricultural rubber type tape. The concrete slab must be dry around the edges to ensure the tape can correctly adhere. The polythene should not be secured using weights or similar as they will potentially affect colour developments in the concrete. Also avoid stacking materials on top of the polythene as this creates microenvironments on the concrete surface. As an extra precaution during construction, old carpet can be placed over the polythene. Cardboard and other cover boards can also be used. These can curl however, and create a work hazard. Do not lay any carpet or similar material directly on the concrete surface as material may leach out and stain and mark concrete, and these materials do not provide adequate protection against liquid contaminants.

The polythene must also be removed at least one week, (ideally ten days), prior to sealing to allow the concrete to dry completely.

Concrete dries slowly so the longer the polythene is off the slab the better, but this will depend on the progress of construction and how much potential there is for contamination – obviously for the painting stage the polythene should remain on.

The concrete surface must be totally dry before you apply sealer. Moisture trapped under the sealer can cause the sealer to whiten or even result in sealer delamination.

To facilitate the drying process, protective covers may be lifted from internal surfaces once curing is complete and the site is weather tight. Externally, once the slab is cured the polythene may be discarded or replaced with more protection that allows the concrete to dry more efficiently (cardboard, for example). However, once the polythene is removed, you need to be careful to avoid the risk of staining and marking of the concrete surface.

Concrete, tiles, pavers or timber for your patio & pool surround.

How to make the right choice.

PeterFell colours can be used in concrete and pavers, so you can use both for your courtyard, patio or pool surround. You just need to be aware that there is a slight tonal difference between how the colour appears in the concrete and the pavers.

Concrete |

Pavers or Tiles |

Timber |

| Natural mottliness and character | More even colour, little mottliness | Natural look |

| Complete design flexibility | Only set sizes possible ie typically 300, 450, or 600mm square | Flexible |

| Colour stable, reseal required every 3-5 years | May get ‘the moon’ light circle in centre | Colour will fade. If staining will need restain every 2-3 years |

| Very cost effective | Usually close to double the cost of concrete | Reasonably cost effective |

| Cracking risk | No cracking risk | Split lengths possible. Splinters probable |

| No weeds | Weeds can grow in cracks | Weeds can grow in cracks |

| With a little maintenance it will last for generations | Pavers may get uneven over time | Warping likely. Will eventually rot |

| Difficult to rectify problems, must be done right first time | Chipped or broken tiles can be removed and replaced | Can replace lengths as required |

| No chance of mosquitos breeding under | No chance of mosquitos breeding under | For those in the north, mosquitos often breed under decks |

Concrete, asphalt or pavers for your driveway and paths?

How to make the right choice.

Concrete |

Asphalt |

Pavers |

| 65+ colours available. | Only black available. | Usually only a few colours available. |

| Colour stable reseal required every 3-5 years | Black fades to grey after a few years | Colour should be stable |

| Very cost effective, slightly more than exposed | Maybe a little cheaper than coloured concrete | More than coloured concrete and asphalt |

| Cracking risk | No cracking risk | Cracked or broken can be replaced |

| No weeds | No weeds | Weeds can grow in cracks |

| With a little maintenance will last for generations | May get humps and hollows if ground issues exist | May get humps and hollows if ground issues exist |

| Difficult to rectify problems, must be done right first time | Asphalt does not perform well long term in areas of heavy turning | Sections can be removed but colour unlikely to match |