Cutting concrete is essential to control cracking.

All newly poured concrete shrinks slightly as it dries which can result in cracks. To control potential cracking the concrete is cut. These cuts are called Construction Cuts – also known as Control or Expansion Cuts.

The placement and timing of these cuts is critical to the performance of the concrete. Construction Cuts are made at places deemed most likely to crack, typically at any change in angles, allowing a maximum area of approximately 16m2. These cuts are typically 3 mm wide and to a depth of one third the depth of the concrete. These cuts must be continuous, not staggered or offset.

As shrinkage begins almost immediately when the concrete is laid, it is essential that the Construction Cuts are executed within 24 hours of placement. Subsequently, it critical that the Construction Cuts are planned prior to the commencement of any concrete.

While Construction Cuts are the most common way to control cracking, other jointing methods are available – consult with your architect or engineer about other options.

Cutting can also but be used to add visual interest.

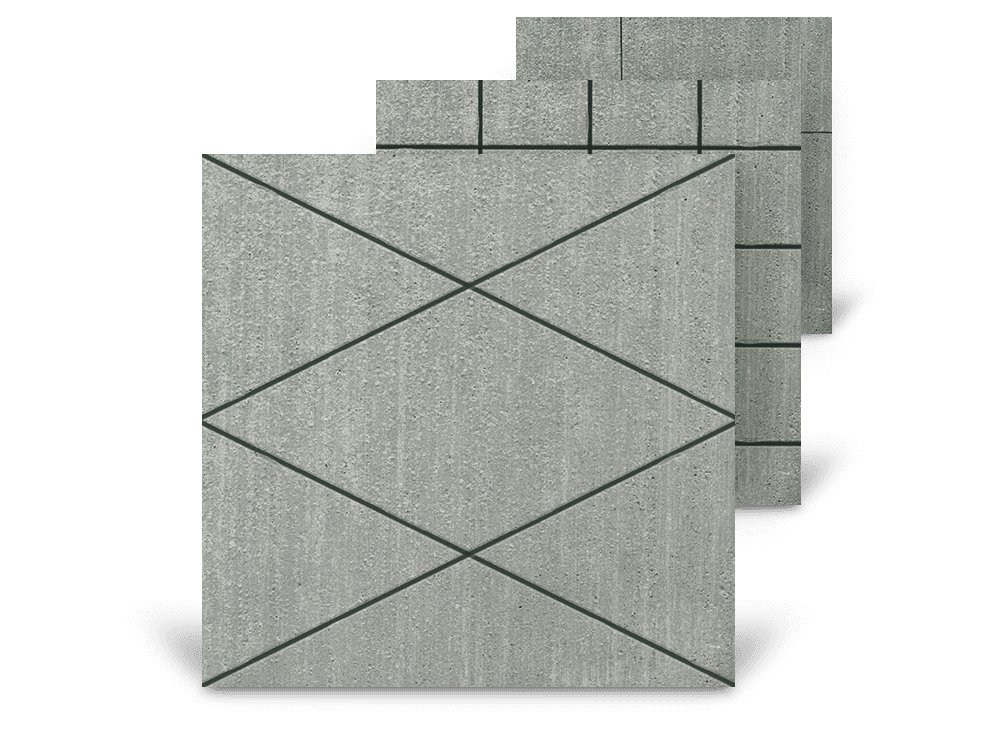

While Construction Cuts are critical to control cracking, additional cuts – called Decorative Cuts, can be employed for aesthetic effect to create a pattern on the surface.

Decorative cuts can be placed anywhere and can be executed at any time, even months later. The concrete must be of sufficient strength (10 – 20 days post pour) to ensure a clean cut, if the concrete is too soft, a jagged edge can result. Similarly, if continuous cuts are required through multiple rooms, cutting must be conducted prior to framing.

Decorative Cuts are typically 9 – 13 mm wide, and only penetrate the concrete 10 – 15 mm. If Decorative Cuts are being employed, they are also applied over the Construction Cuts, to make all cuts the same in appearance. These wider cuts give more of a tile or flagstone look and are much easier to grout than Construction Cuts alone.

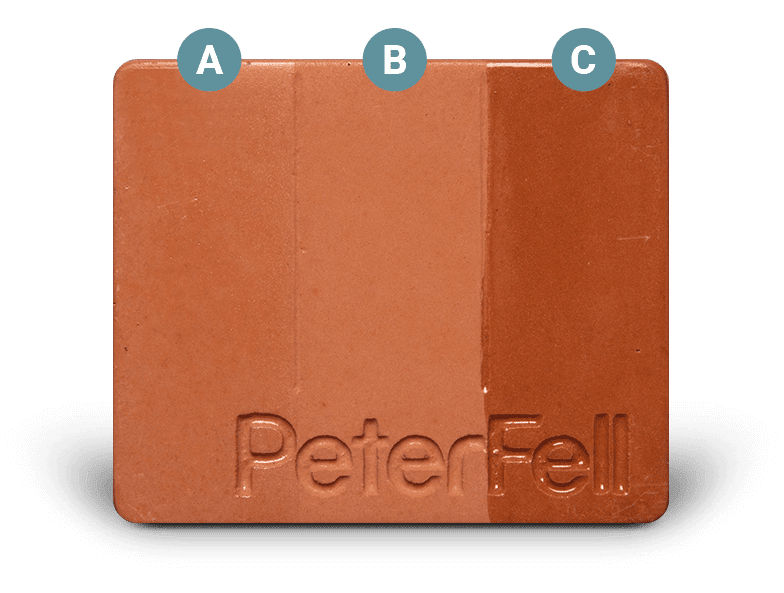

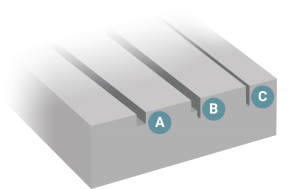

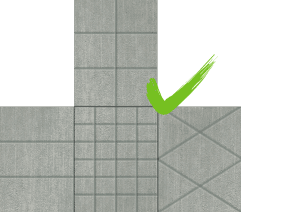

A = Decorative Cut

B = Combination of Construction Cut and Decorative Cut

C = Construction Cut

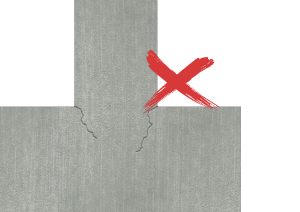

Shrinkage crack likely to originate from changes in angles in concrete slab without Construction Cut.

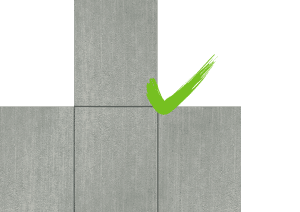

Construction Cuts are required to control concrete cracking.

Decorative Cuts (usually not as deep as Construction Cuts) can be placed around the required Construction Cuts to form a pattern.

Grouting.

The cuts are filled with a coloured grout to complete the look. To finish the pattern, the cuts are filled with our special concrete grout.

This grout can be coloured using any PeterFell colour. Commonly people choose to have the grout the same colour as the concrete. As the grout is slightly darker than concrete, the colour will have a slight tonal difference, giving a subtle contrast to the pattern. The surface of the grout may be flush with the surface or slightly concave. It’s all about the look you want to create.

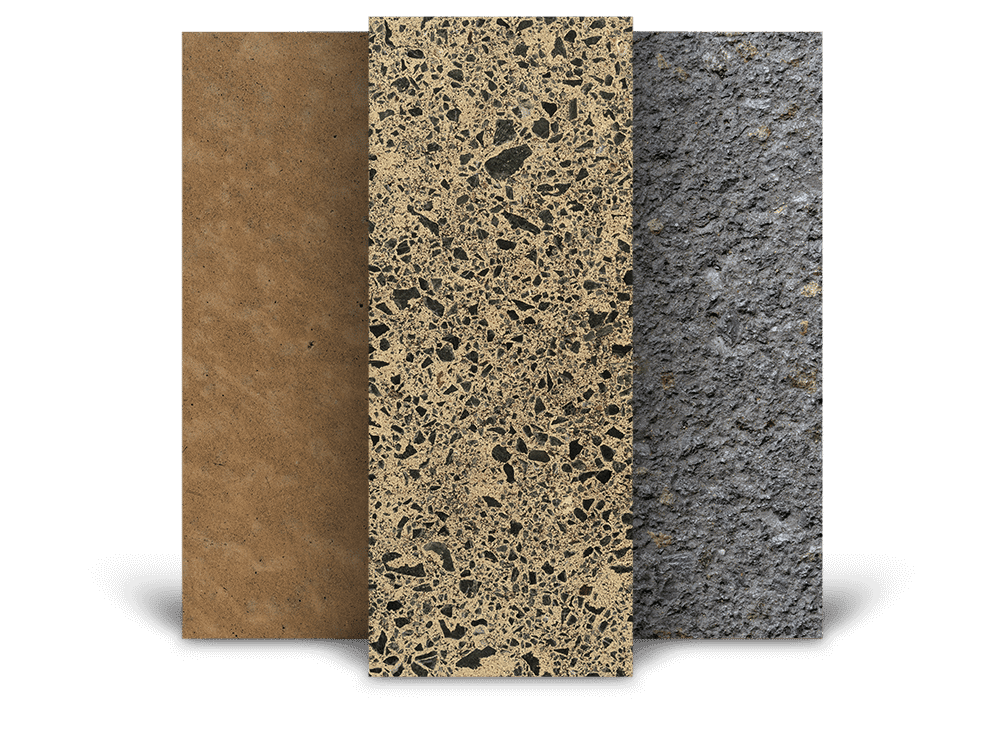

Timber, tile, ceramic, brass, steel inlays.

A wide variety of material can be placed into concrete for decorative effect.

There are two general techniques. The first is the direct method. Here the in-lay is fixed first and the concrete poured around it. The second is the indirect method, where an area is boxed off when the concrete is poured and the in-lay inserted later. You need to be careful that the concrete will not taint the inlay as it is very alkaline. The best method is often determined by the type of insert being used – consult with your architect/engineer or project manager to insure the inlay is suitable.

Frequently asked questions.

Do I have to cut my concrete?

Yes. All concrete needs to be cut to reduce the risk of cracking as the concrete dries. These cuts are called Construction Cuts (also called Construction joints, Expansion Cuts, or Expansion joints) and must be correctly positioned and done within 24 hours of the concrete being poured, otherwise there is a significant risk of concrete cracking (unless other jointing methods are used).

What types of cuts are there?

The PeterFell System uses two types of cuts:

- Construction Cuts (which reduces the risk of cracking); and

- Decorative Cuts. These are used to create patterns on the surface of the concrete.

How do I indicate where the cuts need to go?

Use a crayon as this can be easily removed from the concrete. Do not use string lines or coloured chalk as they are difficult to remove.

Where do the Decorative Cuts go?

These can be placed anywhere in the concrete and can be made at any time. We do recommend, however, that you make Decorative Cuts five to ten days after the concrete is laid. During this time the concrete will be strong enough to enable a clean cut face, and still be soft enough to make cutting easy. If the concrete is too soft there is an increased chance that aggregate can be dislodged during cutting, resulting in jagged cut edges.

If you want a continuous Decorative Cut pattern, ensure that cutting is complete before any framing or other physical obstructions are placed on the concrete. If such limitations exist, cuts can be made parallel to the framing (or obstacle) to generate a border.

Decorative Cuts are wider than Construction Cuts. They’re typically done with a 10 mm saw blade (generating 9-13 mm cut), and only penetrate 10-15 mm into the slab. The only limitation on the width and depth of the Decorative Cut is that they need to be able to be grouted, which is difficult if they are too thin or deep.

Decorative Cuts are placed over Construction Cuts to allow grouting, and to integrate the Construction Cuts into the decorative pattern. The placement of the Decorative Cuts is limited only by the Construction Cuts. Contact us for ideas on how you can incorporate Decorative Cuts into your space.

Where do the Construction cuts go?

The placement of Construction Cuts must be decided before any concrete work begins. As concrete hardens (cures), excess water evaporates causing the concrete to shrink and so crack. Construction Cuts should be made shortly after the concrete is placed to control random shrinkage cracking. As the concrete hardens, cracking occurs beneath the sawn slot when shrinkage exceeds the tensile strength of the concrete. As shrinkage begins almost immediately following placement, it is vital that the Construction Cuts are done within 24 hours of placement. Cutting too early causes ravelin or aggregate dislodgement, causing joint spalls. Sawing too late may mean uncontrolled cracking. Liaison between concrete cutter and concrete placer is paramount to ensure cutting is made at the right time.

All Construction Cuts should be continuous, not staggered or offset. Cuts must incorporate any changes of angles in slab layout. When the Construction Cut cannot be carried to the edge of the slab, due to either physical or design limitations, a crack is likely to radiate from the end of the cut to the slab edge. Whilst the positioning of Construction Cuts is determined by the concrete design, consideration should be given to the placement of the Decorative Cuts i.e. if you want a decorative diamond pattern, the Construction Cuts can be made at a 45 degree angle, instead of 90 degree angle (which would create a square pattern).

Construction Cuts are typically 3 mm wide and cut to a depth of one third the depth of the concrete. Vertical loads are transmitted across the joint by aggregate interlock between the opposite faces of the crack, providing the crack is not wide. If the saw cut is too shallow then random cracking will occur. If the saw cut is too deep, aggregate interlock may be insufficient to transfer vertical loads.

Concrete slabs should be cut allowing a maximum area of 16m2 for an average slab (approximately 100 m2). Decorative Cuts (see following section) should be placed over the Construction Cuts to incorporate them into the cut pattern and enable the cut to be grouted.

While cutting is the most common jointing process, there are other options available. Talk to an engineer or concrete technician for more details.

What size cuts can I have?

You can customise the size and shape of the cut pattern to create the look you want. The only limitation you want. Contact us for further advice on the use of decorative cuts.

Who does the cutting?

This can be done by any competent concrete cutter and is usually arranged by the concrete contractor. Construction cuts are made as for any standard concrete work.

What are the cuts filled with?

Decorative Cuts should be filled with Non-Shrink Grout. This is a specially designed shrinkage-compensated grout that has excellent substrate adhesion, is non-corrosive, non-toxic, and impact resistant.

We recommend that grouting is done using a Grout Gun to stop contamination of the area next to the cut. An option is to use a trowel, as long as cuts are lined with Grout Tape.

What colours does PeterFell Non-Shrink Grout come in?

You can use any colour from the PeterFell range for your PeterFell Non-Shrink Grout.

Usually the grout colour is the same as the concrete colour. As PeterFell Non-Shrink Grout has a slightly darker base colour than concrete, it will appear darker when oxide is used in the grout, creating a subtle contrast. You may want to use a contrasting colour altogether, or leave the grout in its natural colour.