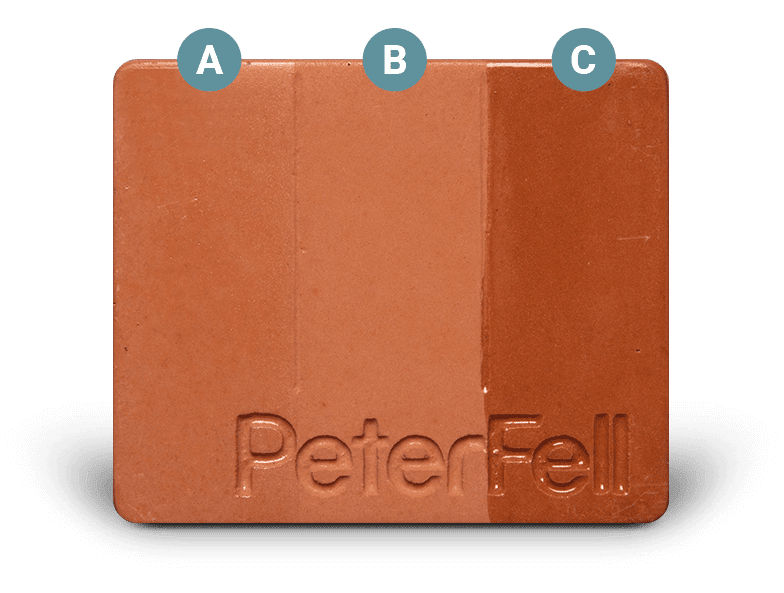

The surface texture is created when your concrete is laid and defines the overall colour, look and feel of your concrete.

There is a huge range of textures and finishes to choose from, and it is important that the texture chosen is appropriate for the environment i.e. non-slip for a pool surround, or smooth and easy to clean for a house floor. The concrete contractor creates the concrete surface, so it’s important that you let the contractor know what texture and finish you want to achieve.

All concrete should be laid in accordance with Standards New Zealand NZS3109 and textured in accordance with Standards New Zealand NZS3114. In addition to these guidelines, further detail on the required texture must be specified using the guidelines below.

Interior (smooth texture)

All concrete is screeded (U1) and mechanically floated (U2) prior to application of the specified texture.

Smooth Trowel

| Finish: | Smooth |

| Technique: | Hard trowelling to remove float marks to generate smooth concrete surface. |

| Class: | U2/U3 |

| Notes: | Standard internal finish for residential floors. Manual or mechanical steel trowelling of floated finish after concrete is sufficiently hardened, or where smooth finish is required. |

| Application: | Floors, Commercial |

Light Trowel

| Finish: | Smooth |

| Technique: | Light trowelling generating smooth surface with visible trowel marks. |

| Class: | U2/U3 |

| Notes: | Smooth finish for residential floors with trowel marks visible on the surface. |

| Application: | Floors |

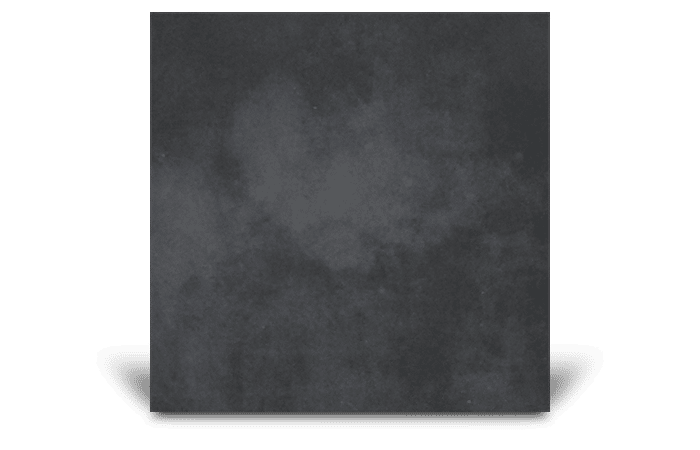

Natural Polish

| Finish: | Smooth |

| Technique: | Low speed stone grinding of concrete surface with ought exposing any aggregate. |

| Class: | U11 |

| Notes: | Generates very smooth surface with no aggregate visible. |

| Application: | Floors, Commercial |

Salt and Pepper Grind

| Finish: | Smooth |

| Technique: | Low speed stone grinding of concrete surface exposing tips of aggregate. |

| Class: | U11 |

| Application: | Floors, Commercial |

Light Grind

| Finish: | Smooth |

| Technique: | Low speed stone grinding of concrete surface exposing tips of aggregate. |

| Class: | U11 |

| Application: | Floors, Commercial |

Medium Grind

| Finish: | Smooth |

| Technique: | Low speed stone grinding of concrete surface exposing mid level of aggregate. |

| Class: | U11 |

| Application: | Floors, Commercial |

Heavy Grind

| Finish: | Smooth |

| Technique: | Low speed stone grinding of concrete surface exposing significant level of aggregate. |

| Class: | U11 |

| Application: | Floors, Commercial |

Machined

| Finish: | Smooth |

| Technique: | Vibrating or oscillating screed. May supplement with long handled float. |

| Class: | U4 |

| Notes: | Used to increase durability of concrete surface. General commercial application for floors subject to heavy machinery or high use. |

| Application: | Commercial |

Exterior (non-slip texture)

All concrete is screeded (U1) and mechanically floated (U2) prior to application of the specified texture.

Medium Trowel

| Finish: | Non-slip |

| Technique: | Trowelling of floated finish to impart texture to the surface. |

| Class: | U2/U3 |

| Notes: | Textured finish for external residential concrete surfaces, ideal for patios and pool surrounds. |

| Application: | Patios, Pool Surrounds, Driveways & Paths |

Rough Trowel

| Finish: | Non-slip |

| Technique: | Heavy trowelling of floated finish to give a rough textured surface. |

| Class: | U2/U3 |

| Notes: | Very textured finish for external residential concrete surfaces, ideal for driveways and paths. |

| Application: | Driveways & Paths, Pool Surrounds, Public Spaces |

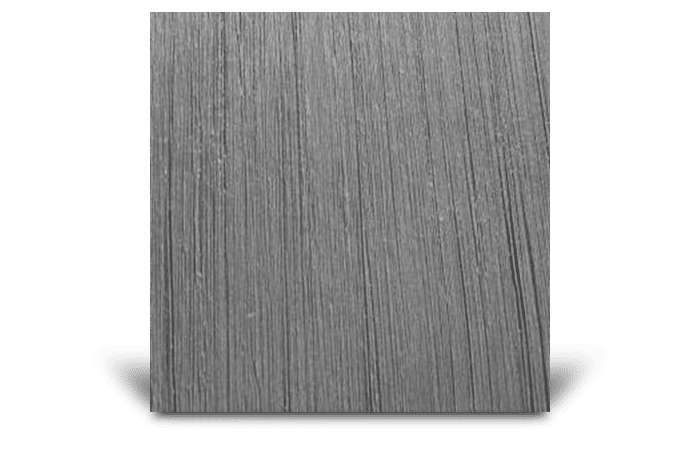

Light Broom

| Finish: | Non-slip |

| Technique: | Soft bristle broom dragged over surface to impart texture. |

| Class: | U5 |

| Notes: | Very textured finish for external residential concrete surfaces, ideal for driveways and paths. |

| Application: | Driveways & Paths, Public Spaces |

Heavy Broom

| Finish: | Non-slip |

| Technique: | Hard bristle broom dragged over surface to impart rough texture. |

| Class: | U5/U6 |

| Notes: | Very rough textured finish for external surfaces with significant slope or areas where non-slip required |

| Application: | Driveways & Paths, Public Spaces |

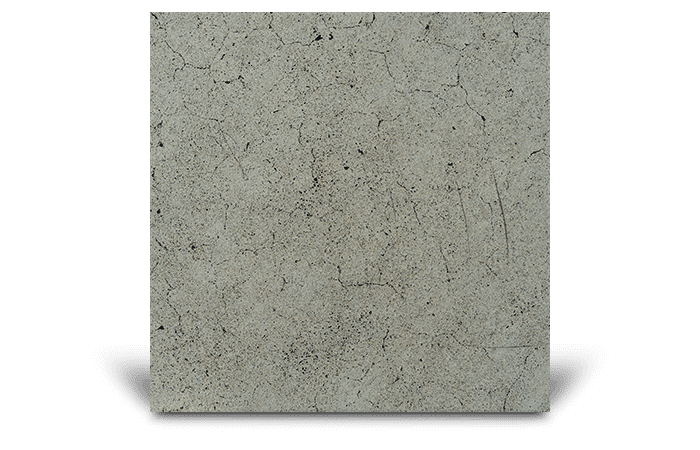

Sandstone

| Finish: | Non-slip |

| Technique: | Concrete surface etched with acidic solution to expose sands and fines. |

| Class: | U10 |

| Notes: | Gives concrete a subtle texture and a ‘sandstone; appearance. |

| Application: | Patios, Pool Surrounds, Driveways & Paths |

Texture Roll

| Finish: | Non-slip |

| Technique: | Dimpled roller used to texture concrete. |

| Class: | U10 |

| Notes: | Gives a subtle dimpled texture to concrete surface. |

| Application: | Patios, Driveways & Paths, Pool surrounds, Public Space. |

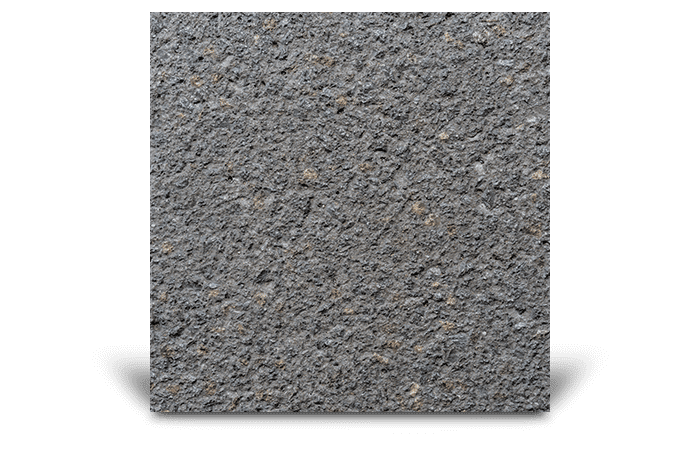

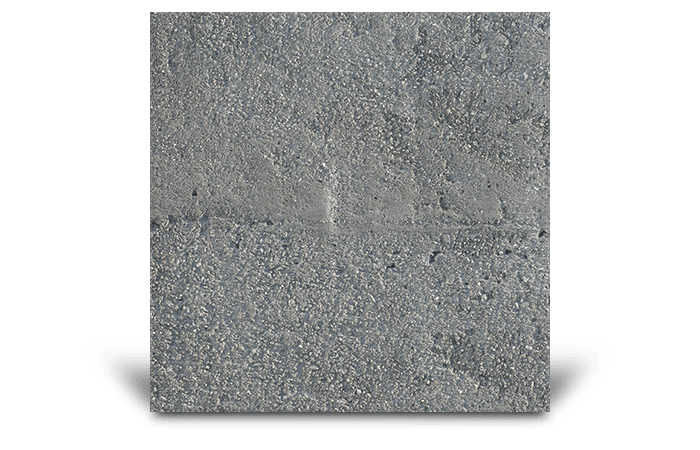

Bush Hammer

| Finish: | Non-slip |

| Technique: | Mechanical hammering of hardened concrete. |

| Class: | U9 |

| Notes: | Method of texturing existing concrete where a non slip surface is required. |

| Application: | Public Spaces, Driveways & Paths |

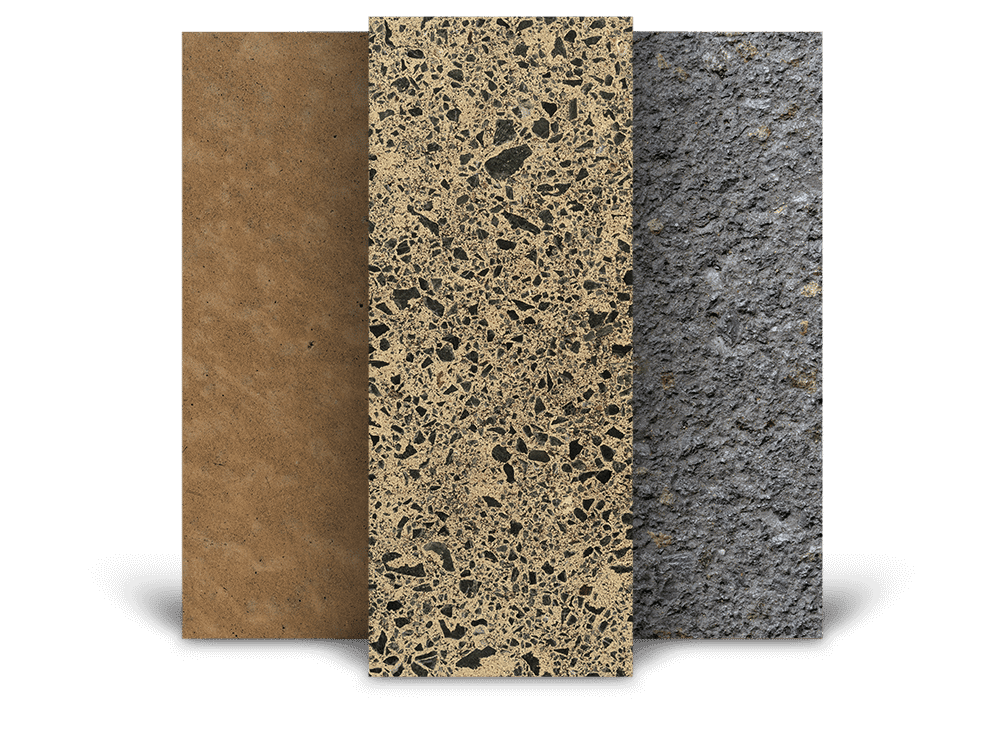

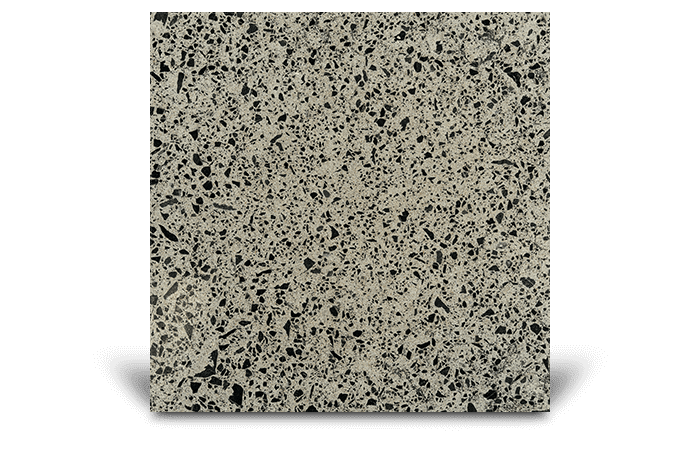

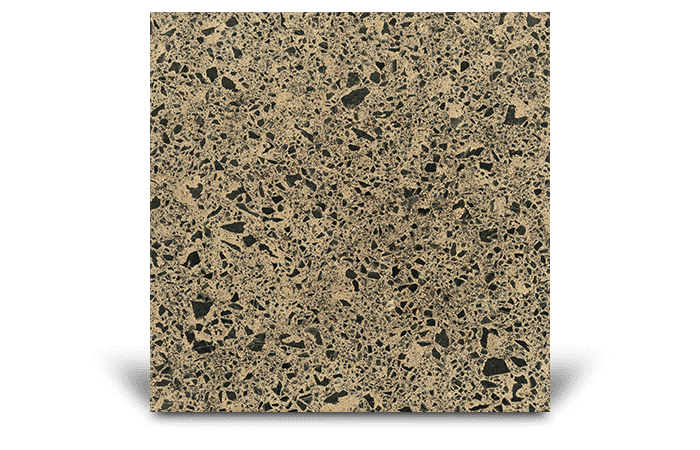

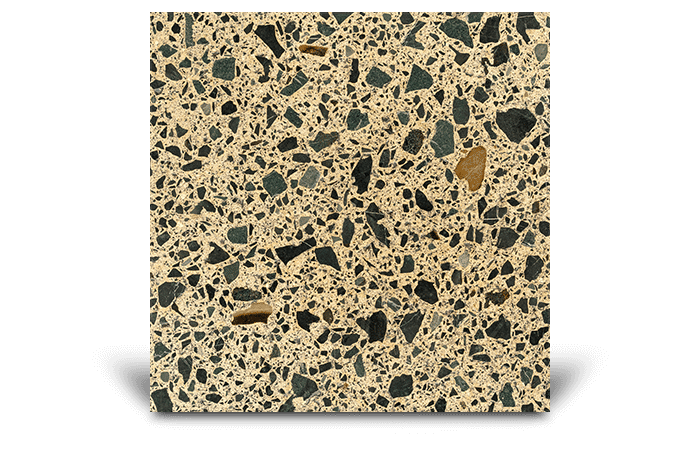

Exposed Aggregate

| Finish: | Non-slip |

| Technique: | Aggregate exposed at time of placement. |

| Class: | U5E (F5E) |

| Notes: | Aggregate prominent both aesthetically and texturally. |

| Application: | Driveways, Paths, Walls, Public Spaces |

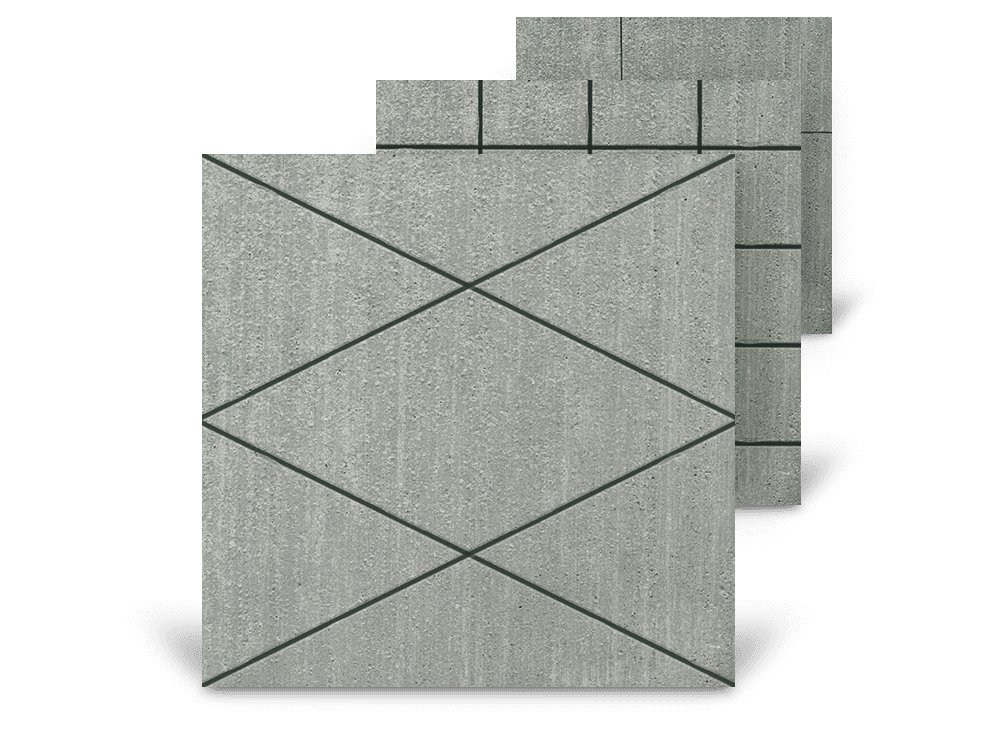

Textures for walls

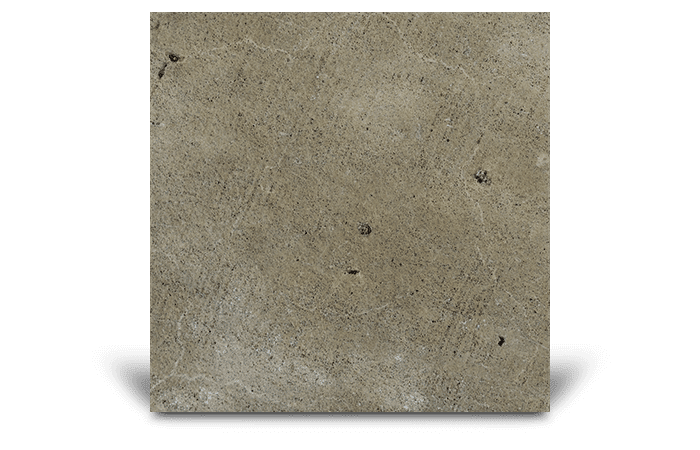

Fair-faced concrete

| Finish: | Smooth |

| Technique: | Cast or poured into smooth lined form work. |

| Class: | U10 (F6) |

| Notes: | Simple clean flat surface. |

| Application: | Walls, Public Spaces |

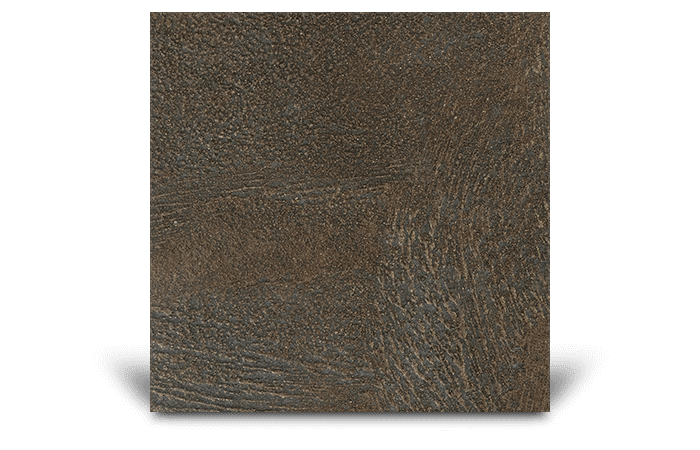

Textured / Decorative

| Finish: | Can be rough texture or smooth shapes. |

| Technique: | Textured mould or form work. Can be rough timber of custom silicon mould. Some texture can be applied later i.e. acid washing, polishing |

| Class: | U10 (F6) |

| Notes: | A great way to add interest to walls and precast panels. |

| Application: | Walls, Public Spaces |